Procut - 250 New model 2019

The robust and compact equipment for stock labels production.

This serie of machines was developed thinking in the handling of the operator. Standard items included: Simplified die cutting unit for speed up the set-up time and improved production speed, up to 100m/min (62"/sec).

The ideal solution for starting business that needs also a robust equipment with industrial features.

Technical specification:

-Max width: 250mm

-Maximum speed: 100m/min

-Cutter units: 2 (1 front and 1 back)

-Cutting system: solid die or magnetic cylinder with flexible dies (not included)

-Rewind shafts: 3 units, 3"core

-unwind shafts: 1 units, 3 "core.

-Touch screen 7'' display

-Advanced production software with label counter, roll counter,

meter counter etc.

-240v, single phase, 2Kw

-EU Industry 4.0 Ready*

Optionals for Procut-250

Webguide automatic, slitting tool, magnetic cylinders.

Download Brochure: Procut250.pdf

Variety of substrates you can print on:

-Paper

-Plastic BOPP / OPP

-Films Poly

-Textile

-Rubber

-syntetic cork

-and almost any material supplied in rolls.

It can print on standard paper (no expensive treated/coated paper needed)

The 250mm (10") width is an ideal size for small and medium jobs due the short setup time.

Also this format offers low cost printing plates and flexible Blades.

The paper path is extremely optimized for minimal waste.

Available low cost inks:

-Water based

-Solvent based

-Ethanol (alcohol) based

-Epox bi component

-UV (with UV optional dryier)

Single phase 220v. (no need 3 phase)

Download here the Brochure: Procut Primepress.pdf

Exclusive easy to operate printing units.

-No tools needed.

-No pressure adjustment needed between job changes.

Modular Flexo press

You can mount the machine as you need, starting from the Procut frame, adding flexographic printing units up to 6 colors.

Excellent printing quality with the exclusive quick lock system for the printing cylinder and anilox roller.

Fastrack Mini 220

Machine for finishing labels printed by digital printers. It uses the Semi-rotary cutting technology in a very compact body.

The Fastrack Mini is simple to operate and it offers stability for small and long jobs. It uses flexible blades attached on a magnetic cylinder.

Technical specification:

Maximum width: 220mm (8.6"), Cutting units: 1, Semi rotary, cut to register

Download here the brochure: FastrackMini220V.pdf

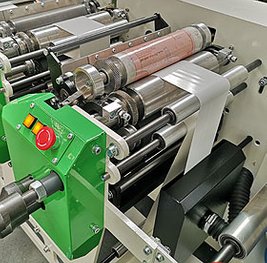

Fastrack 5000 series

The Fastrack system was well thought out and built to last. This machine can Cut-to-register any label printed in rolls. It uses an special black mark sensor to syncronize the image with the blade.

This model is already in the fifth generation, and the new version can reach high cutting 40m/min in Semi-Rotary mode at 350mm of maximum width.

The powerful CNC controller positionate precisely the cutting tool thru servo motors and executes the kisscuting with remarkable precision.

Typical problems with waterproofing can be eliminated by applying the lamination

or varnish (5400/5600 series), it also allows for convenient operation with large roll media. The external diameter is about 700 mm (close to 2000 running meters).

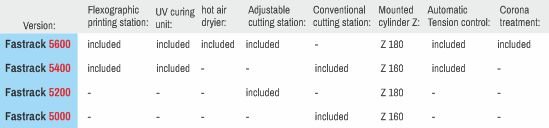

4 different models are available from the 5000 series. See here on the chart the details for each version:

4 different models are available from the 5000 series. See here on the chart the details for each version

Technical specification:

-Max width: 350mm

-Max lenght: 420mm (optional 600mm)

-Maximum speed: 40m/min

-Cutter units: 1

-Cutting system:Magnetic cylinder with flexible blades.

-Slitting units: 1

-Printing Units: Optional, flexographic

-400V 3 phase, 4Kw up to 13Kw

Download Brochure here: Fastrack 5000 series.pdf

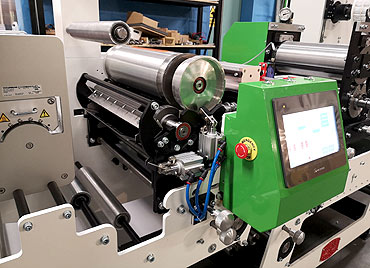

Fastrack Print Flexo UV

Printing using the industrial flexographic system. It requires the photopolymer matrix cliche and the UV ink

This semi rotary flexographic UV printer is a universal printing to register system roll to roll. It is able to print in almost any substrate without any treatment using strong UV inks for different sectors such as Healthcare, Insurance, Food, Clothes etc.

The ideal solutiion for abrasion resistant, waterproof, strong prints with ultra low cost if compared to digital systems.

Main Applications:

-Spot varnishing, glossy or matte

-Print using special colors such as fluorescent, mettalic, pantone etc.

-Print using secutity inks such as magnetic ink, glow ink, safety inks, thermal inks etc.

Technical specification:

-Maximum printing width: 250 or 350mm

-Maximum printing length:320mm

-Maximum speed: up to 12m/min (when using a photopolimer of 300mm)

-Printing system: Flexographic, open chamber, dr blade

-Ink type: Conventional flexographic UV inks

-Curing system: LED UV

-Automatic webguide

-Optical sensor for sincronism and repass feature

-Unwinder and rewinder for 76mm core tubes

-7" display with advanced functions such as label counter, cliche virtual distortion, jump marks, check missing labels etc.

-400Kg, 3Kw single phase 220v

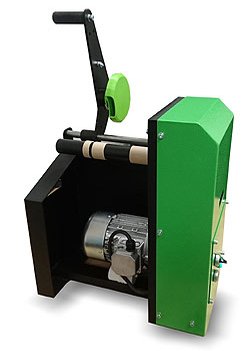

Paper core cutter

Ideal equipment for cutting your carton tubes.

Ultra compact size, it includes the 3 different shafts for cutting tubes of 25mm, 40mm, and 76mm.

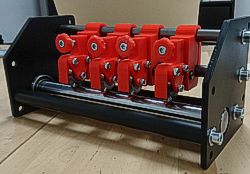

Slitting disc Holder

The most useful auxiliary tool for sliting rolls.

Totally adjustable, it can make half-cut (kisscut) or total cut.

These holders can be mounted in our special designed brackets that fits the Procut, Ni, and Fastrack series.

Or we can design an special support for mounting these holders in your machine.

Contact us to get a quote

Looking for rotary tools?

We can develop the rotary tool for your application!

Contact us for more information

Meccanica Maggiore Srl. P.Iva/CF 03366811200 2019 Copyright © All Rights Reserved contact: info@meccanicamaggiore.com